Plastic Automotive Mold are used to produce large batch […]

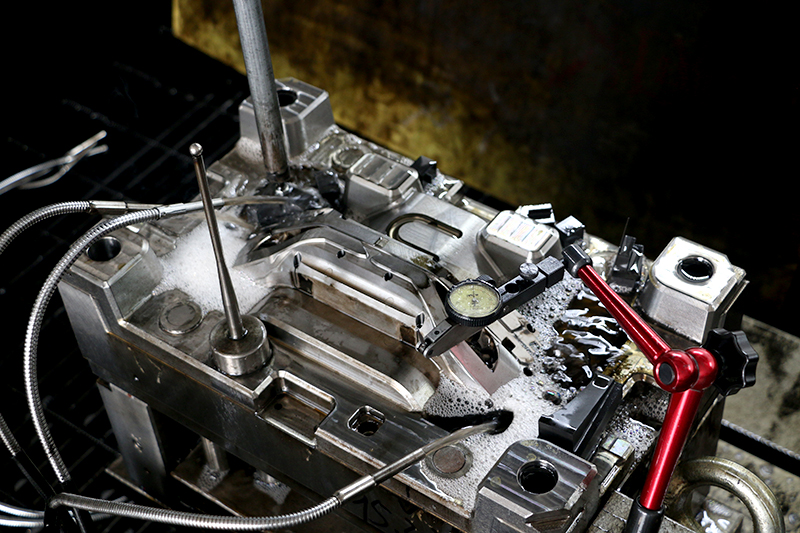

Plastic Automotive Mold are used to produce large batches of injection molded parts. They have the advantages of high efficiency, good quality, less cutting, energy saving and raw materials, and low cost. However, because of the complex processing of plastic molding molds, many problems will be encountered. This chapter will introduce plastics. Problems easily encountered in forming mold processing.

1. Huge size and weight

How to deal with its own huge size and weight is a major challenge faced by plastic molding mold processing plants when processing large-volume plastic molding molds. The processing of large plastic molding molds often requires a lot of labor, special equipment, and multiple adjustments and clamping, and the processing accuracy of plastic molding molds is affected by a variety of potential factors, and it is difficult to guarantee.

2. Expensive purchase cost

The costs directly related to the processing and production of various large-scale plastic molding molds are the costs of professional processing equipment. The machine tools that can make large-scale plastic molding molds are very expensive, especially for the arrangement of complex processing techniques, which require the use of many machine tools to complete the entire process from roughing to finishing. Such high initial input costs are also an obstacle for many companies to enter this market. From here, we can see that if the large-modulus roughing and finishing can be realized on a suitable machine tool, even if only one setup is needed for debugging, then many problems will be solved and the processing accuracy of the plastic molding die can be guaranteed.

Taizhou Huangyan Chuangji Mould Industry Co.,Ltd.