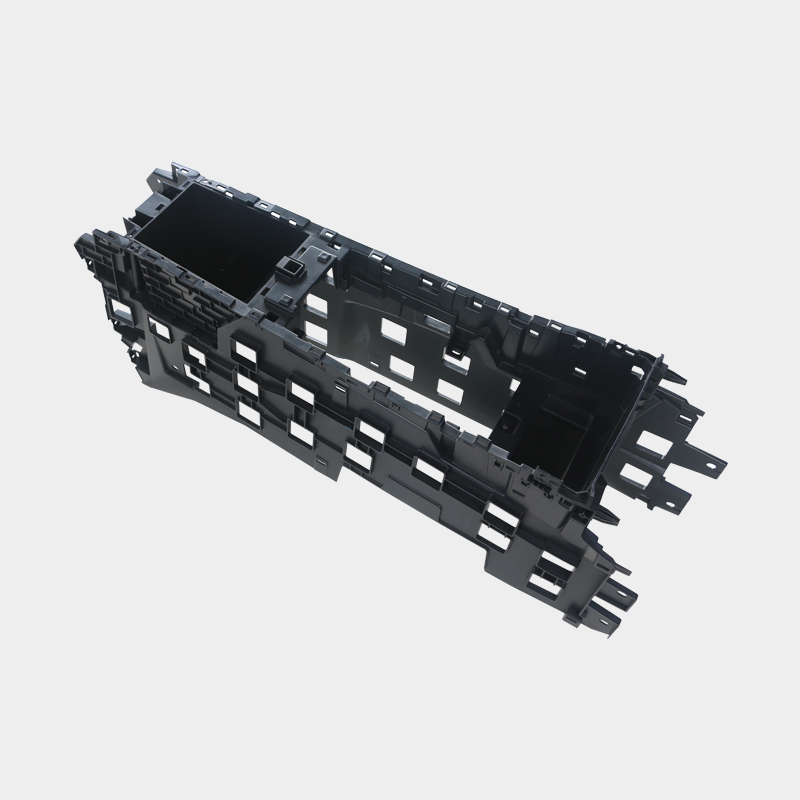

Different injection molded parts need to be made with d […]

Different injection molded parts need to be made with different injection Automotive Mould to meet different product requirements.

Common injection mold types are two-plate molds, three-plate molds, hot runner molds, and right-angle injection molds.

1. Two-plate mold

Two-plate mold, also known as single-parting surface injection mold, is a simple and basic mold type. It is widely used and can be designed into single-cavity molds or multi-cavity molds according to product requirements.

2. Three-plate mold

The three-plate mold is also a double-parting surface injection mold. It is different from a single-parting surface injection mold. In the fixed part, the three-plate mold of this mold is designed with a partially movable stripper plate. In this design, the runner will be ejected between the first and second plates, and the stripper will be ejected between the second and third plates to achieve the purpose of separating the part from the runner. The double parting surface injection mold is not suitable for the molding of large injection parts, because it has the characteristics of complex structure, high manufacturing cost and difficult parts processing.

3. Hot runner mold

The hot runner mold is similar to the traditional cold runner mold. The difference is that the hot runner mold directly injects the plastic into the cavity through the nozzle. There is no runner in the molding process, which greatly improves the utilization rate of raw materials and avoids waste. In general, the manufacturing cost of hot runner mold is higher than that of cold runner mold, but if the molded part is very small, especially if the part is smaller than the runner, the hot runner mold is a more economical choice.

Many mechanical principles are applied in the processing of hot runner molds, especially for multi-cavity molds, processing through hot runner molds can shorten the cycle time required for forming parts, suitable for mass production, and can harvest more benefit.

4. Right-angle injection mold

Right-angle injection molds are not widely used, and are only suitable for angle injection molding machines. Different from other injection molds, when molding, the feeding direction of the mold should be perpendicular to the opening and closing direction, and the cross-sectional area is usually unchanged. In addition, the main channel of the right-angle injection mold is opened on both sides of the moving and fixed mold parting surfaces. At the end of the main channel, in order to prevent the wear and deformation of the injection molding machine nozzle and the main channel inlet, a replaceable runner block.

The basis of a project's success lies in the selection of mold types. Generally, mold engineers will comprehensively consider all factors, including part design, volume, molding environment, installation system, resin usage, and the specific needs of customers, etc., and finally select a suitable one.

Taizhou Huangyan Chuangji Mould Industry Co.,Ltd.