1) Under normal circumstances, the ejection distance of […]

1) Under normal circumstances, the ejection distance of the inclined top of the plastic mold is not very long, and it is easy to break. For plastic molds that can realize fully automated production, the ejection distance of the inclined top can be farther than that of the semi-automatic picking. Fully automatic ejection distance = product height (H) + safety value (K) 5.00~10.00mm; semi-automatic ejection distance = product height (H) X (2/3)

2) The angle range of the inclined roof is 3°~15°, and the optimal range of z is 3°~8°. When the angle of the inclined roof is greater than 12°, in addition to considering the strength, an auxiliary rod must be added to prevent Excessive torque causes deformation and fracture of the inclined top of the plastic mold.

3) The phenomenon of product sticking and inclined top is the most likely to occur in production. The commonly used method is to increase the product demolding angle. When designing, avoid excessive ribs on the inclined top of the plastic mold.

4) The inclined top rod should not be too thin. For small workpieces, the inclined top z should be 3.00mm thick and larger than 500.00mm. The small thickness of the inclined top z should not be less than 25.00mm to prevent the inclined top of the plastic mold from being caused by excessive torque during production. Deformation and fracture.

5) The inclined top of the plastic mold is a kind of ejection mechanism. It is used to eject the product. The area with the inclined top at the same position does not need to be topped, which avoids the interference of the inclined top and the ejection, and the interference of the inclined top and the ejection. Need to do simulation verification.

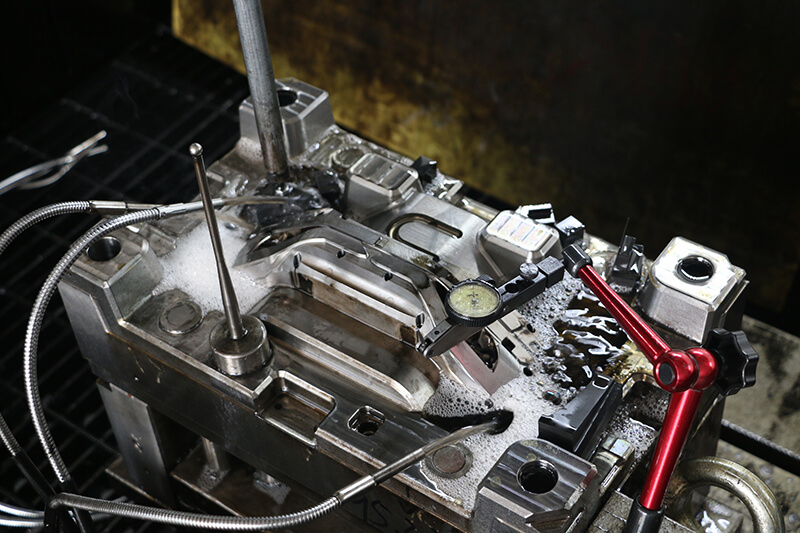

6) In the injection Helmet Mold production, I am afraid that the problems encountered are the distortion of the inclined top and the root fracture. In the design, the inclined angle and the inclined distance of the inclined top of the plastic mold, the material of the inclined top, the size of the inclined top, and the inclined top design Time will have an impact on the inclined roof. Because its structure is relatively easy to damage, it should be carefully repaired and replaced in the injection molding production to avoid hidden dangers such as the front mold sloping top and the sloping top running burrs.

Taizhou Huangyan Chuangji Mould Industry Co.,Ltd.